Security films

Films that ensure the integrity of your documents

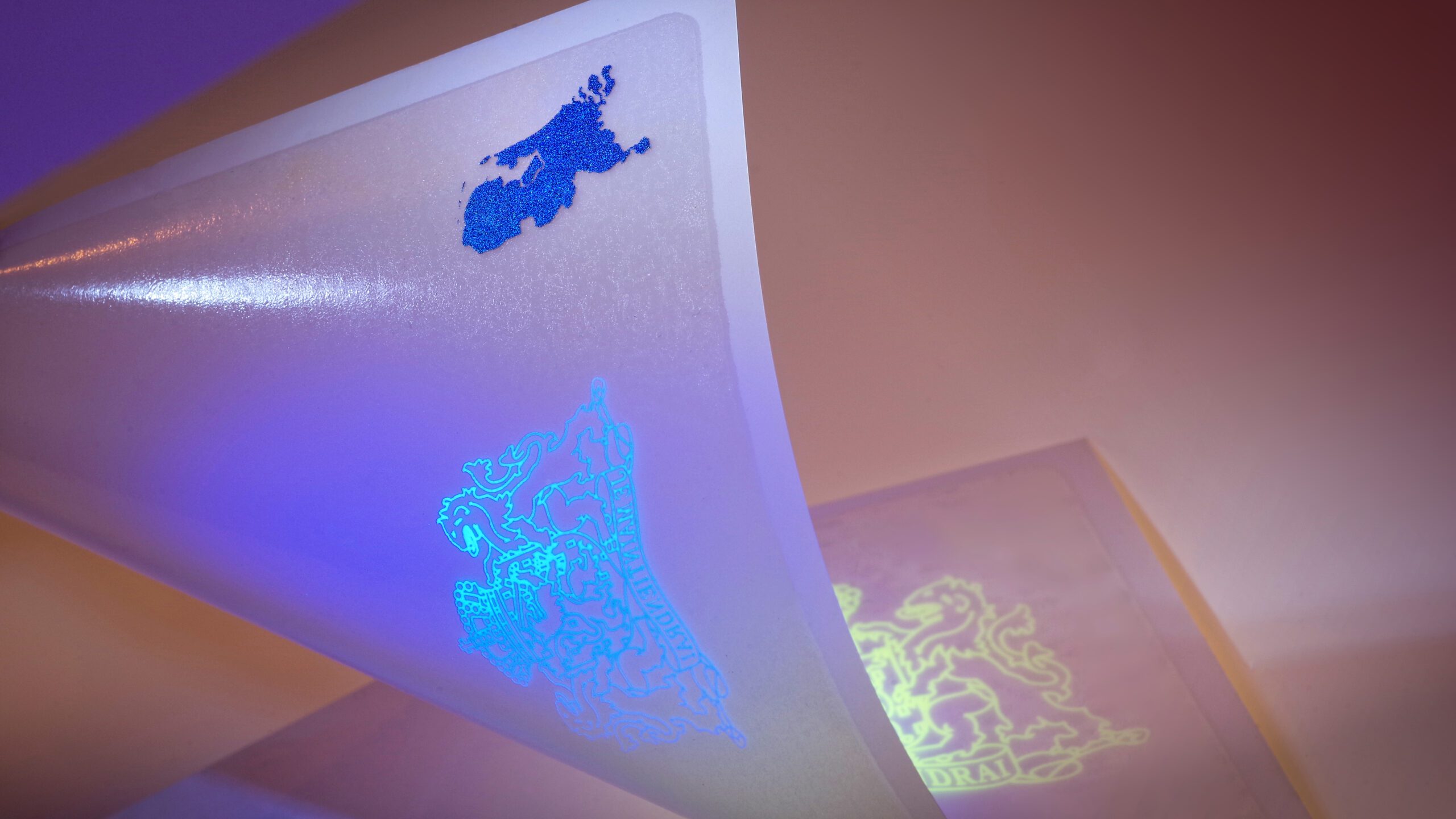

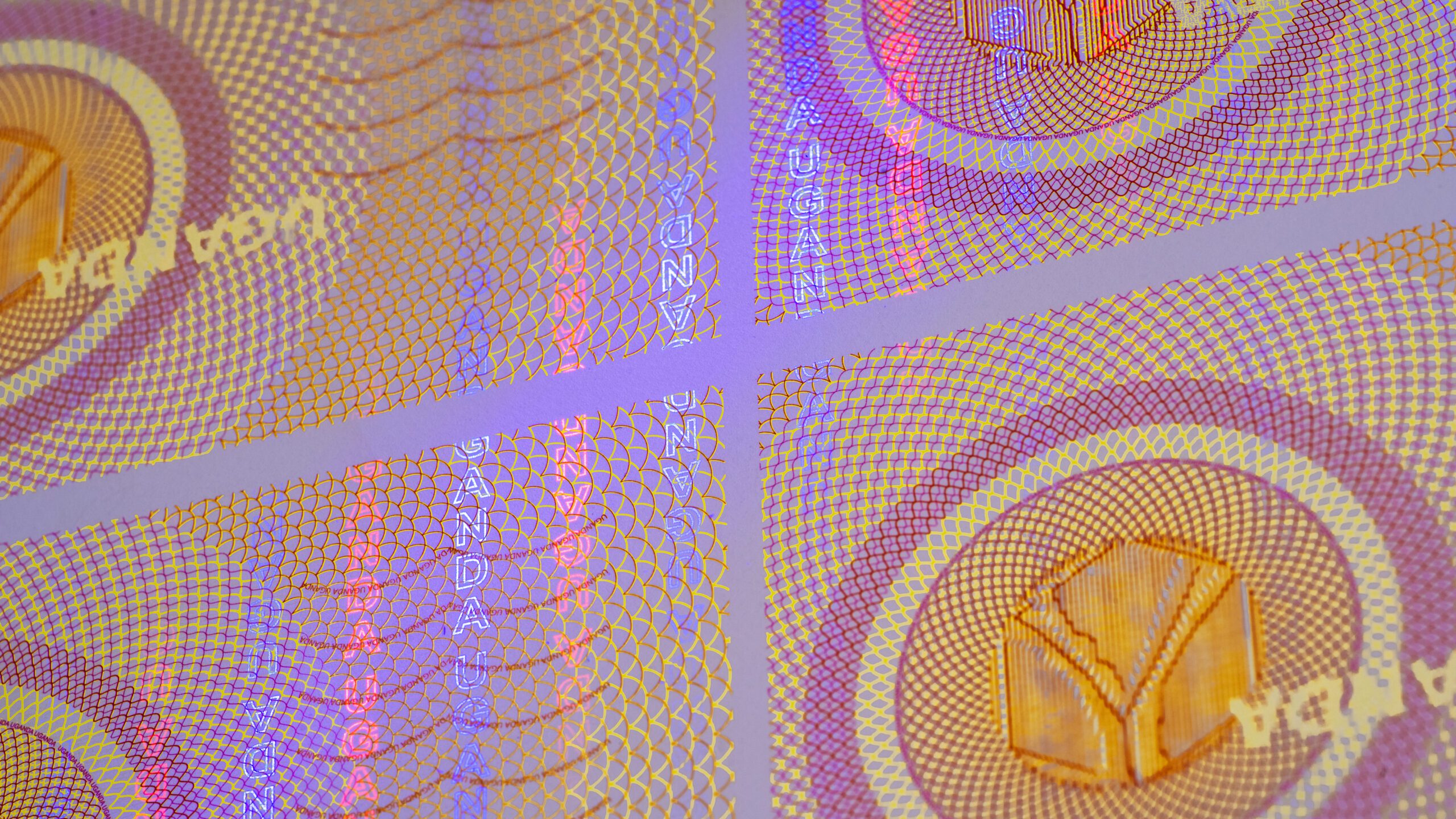

Our security films consist of carefully selected top-of-the-range polyesters and adhesive layers made up of co-polymers. These films form a strong bond with the substrate surface of the document, providing a state-of-the-art security barrier. We can add a wide range of visible (overt) and invisible (covert) verification features and tamper-proofing to these films, so that we can tailor the solution to address specific problems with counterfeiting or fraud. Our R&D department has tested a wide range of compositions of films and their various bonding properties.

We manufacture various formats such as

Film applications

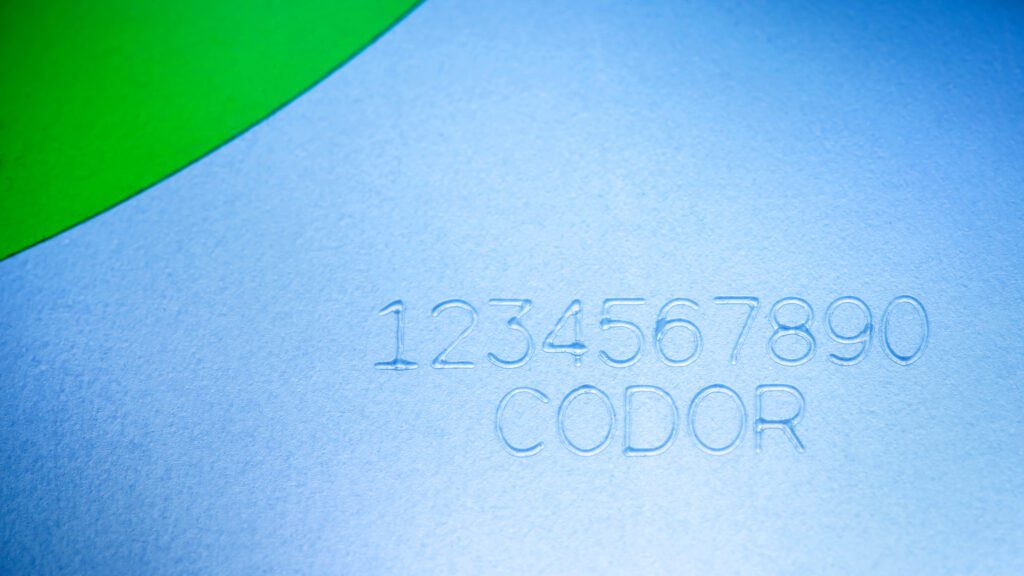

We offer a variety of bespoke overlays and pouches for security documents, including Teslin ID cards, passports, driver’s licenses, residence permits, and election cards. CODOR is also your partner for all types of accreditation badges – from high-security encapsulated paper passes with security printing to Teslin core cards with polycarbonate overlay laminates. We’ll be more than happy to advise you on the best solution for your security document.

Over the years, we have provided turn-key accreditation solutions for a wide range of events. We are a proud supplier to events such as the FIFA World Cup Football, UEFA European Football Championship, and IIHF Ice hockey World Championships, as well as festivals such as World Youth Day Australia.

By combining our film products with our laminators, we can offer you a customized turn-key solution to meet all your security document protection needs.

Detailed information about our films

Security technologies

CODOR takes a comprehensive approach and we know all about the very latest in anti-counterfeiting and anti-fraud technologies. By combining these technologies with the best-quality overlay materials, we can offer you the best solution for your document security challenges.

Ultraviolet ink

Numbering

Embossing

Hologram